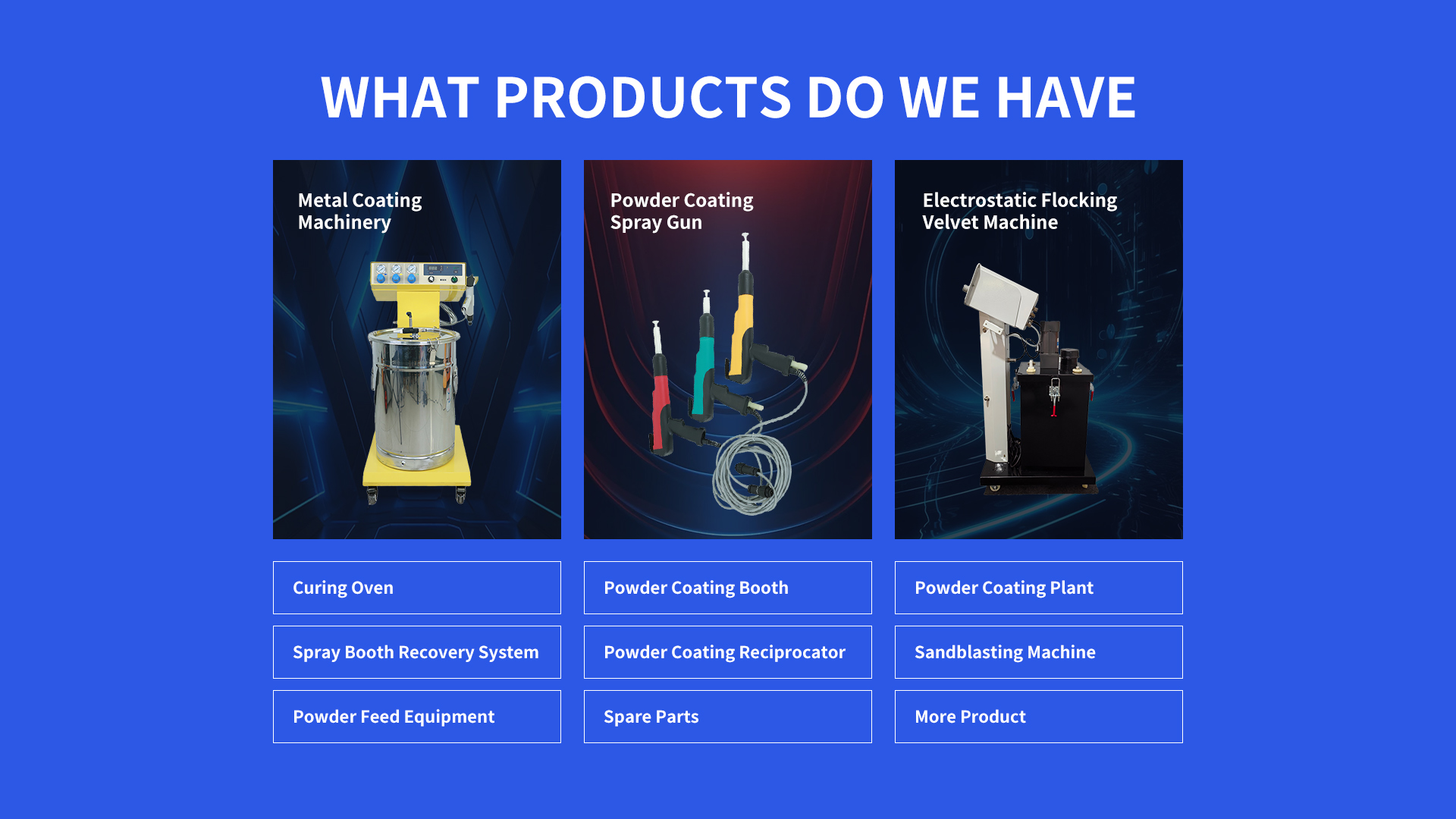

1. Introduction and Structure of Horizontal Powder Coating Line Suppliers' EquipmentHorizontal Powder Coating Line Suppliers provide systems tailored for efficient coating. The main structure features a horizontal conveyor that smoothly transports workpieces. The powder coating booth is outfitted with adjustable, high-performance spray guns for precise powder deposition. The curing oven is engineered to deliver consistent heat, enabling proper powder fusion. Moreover, an efficient powder recovery unit and an intuitive control panel are integral parts, facilitating powder recycling and seamless line operation.

2. Application Scenarios of Horizontal Powder Coating Line Suppliers' Equipment

These suppliers' equipment serves diverse industries. In the machinery manufacturing industry, it coats large metal parts like machine frames and gears for enhanced durability. For the outdoor furniture production, horizontal powder coating lines offer a weather-resistant finish to metal chairs, tables, and benches. In the electrical cabinet manufacturing, it provides a protective and aesthetic coating for metal cabinets.

3. Price of Horizontal Powder Coating Line Suppliers' EquipmentThe cost of equipment from

Horizontal Powder Coating Line Suppliers varies. Basic lines suitable for small-scale operations can start at around $18,000. Mid-range lines with improved features such as better powder control and higher automation levels may cost between $30,000 and $60,000. High-end, fully automated lines with advanced technology can range from $60,000 upwards.

4. Correct Usage Method of Horizontal Powder Coating Line Suppliers' Equipment

Initially, position the workpieces accurately on the horizontal conveyor. Adjust the spray gun settings according to the powder characteristics and workpiece requirements. Preheat the curing oven to the specified temperature. Continuously monitor the coating process as workpieces move along the line and make timely adjustments. Once the curing is complete, carefully unload the coated workpieces.

5. How to Select Equipment from Horizontal Powder Coating Line SuppliersWhen choosing equipment from

Horizontal Powder Coating Line Suppliers, assess your production scale. Look for suppliers with a proven track record of quality and reliability. Evaluate the line's capacity, the efficiency of the powder recovery system, and the stability of the control panel. Also, consider the availability of after-sales support and the ease of customization.

6. Safety Precautions of Horizontal Powder Coating Line Suppliers' Equipment

Safety is of utmost importance. Workers should wear appropriate protective gear, including respirators, gloves, and safety goggles, to safeguard against powder inhalation and potential skin and eye injuries. Ensure sufficient ventilation in the powder coating booth to prevent powder dust accumulation. Regularly inspect the electrical and mechanical components to avoid malfunctions.

7. Rationality Analysis of Horizontal Powder Coating Line Suppliers' EquipmentInvesting in equipment from

Horizontal Powder Coating Line Suppliers is a wise decision. It boosts production efficiency, reduces labor costs, and ensures consistent coating quality. The powder recovery system minimizes waste and saves on material costs. The horizontal layout allows for easy handling of long or large workpieces, enhancing versatility.

8. Q&A about Horizontal Powder Coating Line Suppliers' Equipment

Q1: Can the equipment from horizontal powder coating line suppliers be customized for specific products?

A: Yes, many suppliers offer customization options. You can customize aspects like conveyor length, spray gun types, and control system functions according to your specific product needs for the equipment from horizontal powder coating line suppliers.

Q2: How often should the powder recovery system of the equipment from horizontal powder coating line suppliers be cleaned?

A: It is advisable to clean the powder recovery system at least once a week. Regular cleaning ensures its efficient operation and prevents powder contamination in the equipment from horizontal powder coating line suppliers.

Q3: What's the difference between basic and high-end equipment from horizontal powder coating line suppliers?A: High-end equipment from

Horizontal Powder Coating Line Suppliers offers superior precision in powder application, faster production rates, more advanced control features, and greater durability. Basic equipment is more suitable for simple and low-volume applications.

Q4: Is the installation of equipment from horizontal powder coating line suppliers time-consuming?

A: Installation time varies depending on the complexity of the line. Smaller, simpler lines may take a few days, while larger, more complex lines from horizontal powder coating line suppliers could require a couple of weeks for professional installation.

Q5: How does the temperature control in the curing oven of the equipment affect the coating quality?

A: Precise temperature control in the curing oven is crucial. It ensures that the powder melts and adheres properly to the workpiece, resulting in a uniform and durable coating. Inaccurate temperature control can lead to issues like uneven coating or powder not fully curing for the equipment from horizontal powder coating line suppliers.

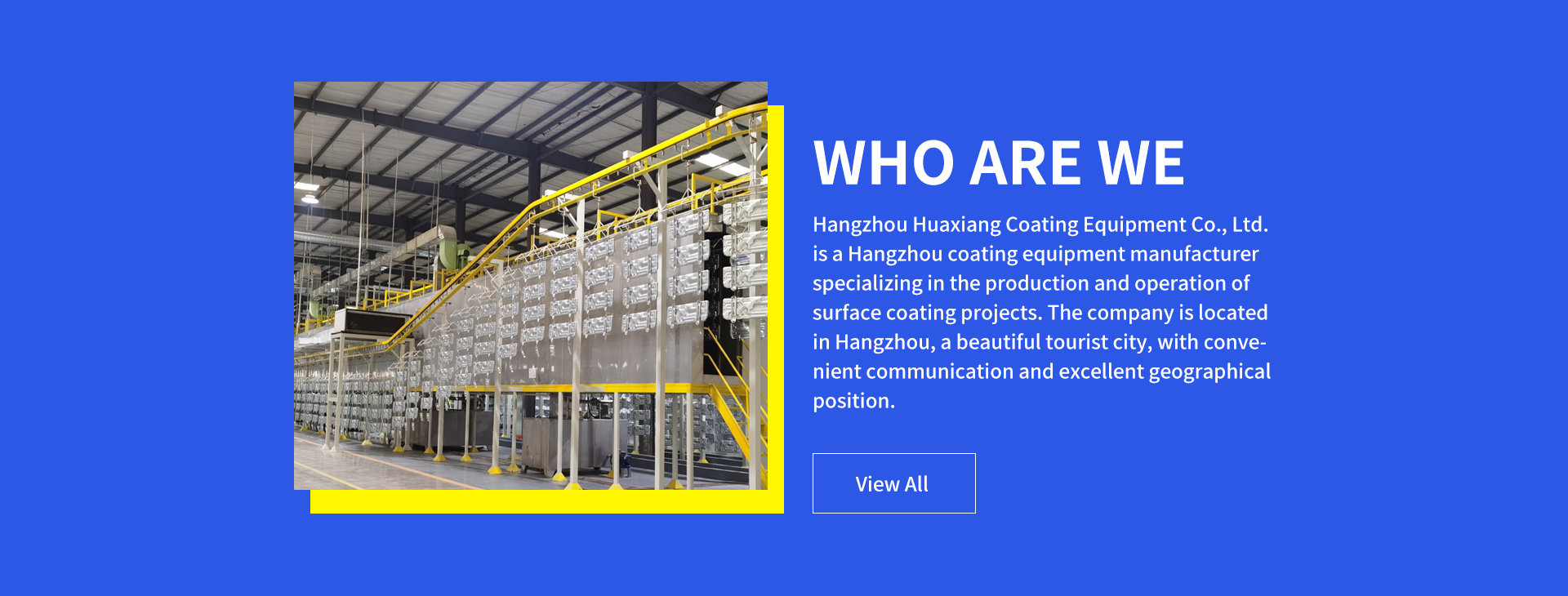

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com